Historical background on inorganic nanocoating technology

- Excellent nanoscience technology similar to the principle of glaze coating on pottery, using the components that make up Mineral=Ceramic

- The principle that even if pottery artifacts buried in the ground or deep sea for a long time are excavated, the surface of the pottery is easily cleaned

The world’s best celadon glaze technology already matured in the 9th to 12th centuries / The world’s best white

porcelain technology matured in the 14th to 16th centuries

- The meticulous coating technology of Si-O bond structure, similar to the glaze coating technology on the surface of celadon - and white porcelain, is the nanotechnology of ceramic minerals

- Excellent technology with high constructability for applying a ceramic coating solution specialized in settling at the nano level by bonding natural minerals and water (H2O) molecules through a coating device

What is Hedori nanocoating?

Comparison of coating surfaces

| Advantage | Power generation efficiency improved by 15% compared to contaminated modules due to excellent self-cleaning effect. The power generation efficiency of nanocoated module is improved by about 3.8-4.7% compared to uncoated modules. |

|---|---|

| Characteristics | - No need for additional maintenance for 5 years after applying single nanocoating - Reduction in module degradation such as bird droppings, corrosion, UV damage, wear, etc., increasing the lifespan of the module |

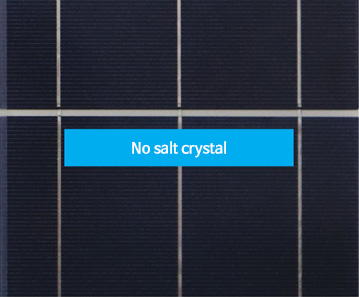

Salt spray test

Collecting sea water

Collecting sea waterApplying sea water

Conventional module

Conventional module

Nanocoated module

Nanocoated moduleTest reports related to the nanocoating

Hydrophilic inorganic nanocoating technology is the patented technology of BK Energy Co., Ltd

, and there are test reports from accredited organizations for increased power generation, no impact on water quality and soil contamination, non-flammability, etc.

Inorganic nanocoating application procedure

Procedures for applying inorganic nano-coating of existing power plant

-

1STEP 01 Water cleaningFirst, remove contaminants using high pressure washing equipment

1STEP 01 Water cleaningFirst, remove contaminants using high pressure washing equipment -

2STEP 02 Applying cleaning processDetermine the type of cleaning solution and whether to use it based on the type and degree of contamination

2STEP 02 Applying cleaning processDetermine the type of cleaning solution and whether to use it based on the type and degree of contamination -

3STEP 03 Cleaning panelsRemove foreign substances on the solar module using high pressure washing equipment and a brush dedicated to solar modules

3STEP 03 Cleaning panelsRemove foreign substances on the solar module using high pressure washing equipment and a brush dedicated to solar modules -

4STEP 04 Applying coating processSimply apply the nanocoating solution generated from the coating solution manufacturing equipment without separate coating equipment (brush, wafer, etc.)

4STEP 04 Applying coating processSimply apply the nanocoating solution generated from the coating solution manufacturing equipment without separate coating equipment (brush, wafer, etc.) -

5STEP 05 DryingDry the applied nanocoating solution naturally

5STEP 05 DryingDry the applied nanocoating solution naturally